- User registration is required to download the materials.

The usage registration form is Click here - Please enter the following items. Go to the download page.

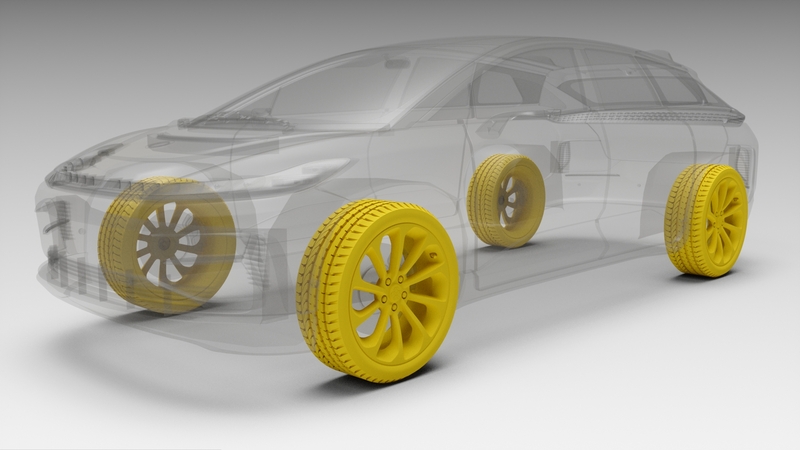

Back Ground

From cap ply to the carcass reinforcement cords, Twaron® can be used in many parts of the tire to add strength and reduce weight.

Twaron® fibers can also be added to rubber compounds of tires to improve the balance between grip, wear, and rolling resistance or to reinforce sidewalls against sharp edge damage from road debris or kerbs. Aramid inclusion in tire design improves safety and lowers carbon emissions.

Overview

One of the most notable characteristics of Twaron® is that it has a much better dimensional stability because of the high crystalline structure of the polymeric molecules. This is particularly important for Electric Vehicle tires where uniformity of tire shape is crucial to providing sensors with accurate data-whether that be relaying data about possible punctures, tire pressure, tread wear etc. As cars become more reliant on electronic sensors and the shift towards an autonomous driving future continues, tire uniformity will become even more important. Aramid is a material that can make that transition possible.

Features

Twaron® outperforms other common tire reinforcement materials such as rayon, polyester, polyamide 66 and steel on strength and modulus.

Due to Twaron®'s extraordinary properties, designers can use less reinforcement material, yet be sure that the tire will perform under high stresss, in all road conditions and even at extremely high speeds. The benefits Twaron® use in tires are:

・High strength

・Improved high-speed performance

・Low rolling resistance: less fuel use, fewer emissions

・Excellent tire shape uniformity

・Easily integrated into production

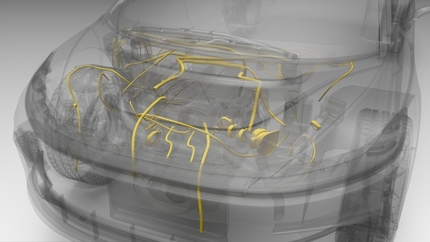

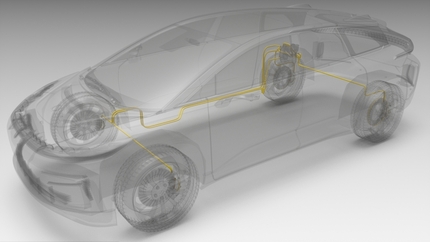

Back Ground

Para-aramid and meta-aramid yarns have outstanding reinforcement properties and offer exceptional resistance to thermal, dynamic and chemical damage. Hoses reinforced with these fibers are strong, durable and can be used under the toughest conditions in the modern era of maintenance-free cars.

Overview

Twaron® and Technora® are para-aramid fibers which have their own unique properies. They are, in general, suitable to reinforce hoses transporting high temperature gas or fluids. Teijinconex® is the recommend product for reinforcement on the hot side of the turbo charger as it can reliably withstand the extremely high temperatures present there.

Teijin Aramid have a large and experienced Reasearch and Development team who can advise stakeholders on selecting the perfect material solution for a particular situation and with that comes the benefits of the Teijin Aramid network with the braiding and knitting machine manufacturers.

Features

With an array of advantageous characteristics Twaron®, Technora® and Teijinconex® represent a formidable palette from which hose makers and automotive stakeholders can draw from to produce a reliable, durable and superior performance.

The benefit of aramid-based solutions in hoses are:

・Heat resistant up to 250 degrees Celsius.

・High chemical resistance (fuel cooling-liquids, and more)

・Decreased chance of leaks and tears

・Retains durability and shape under high pressure and temperature.

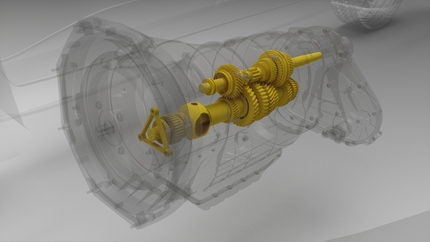

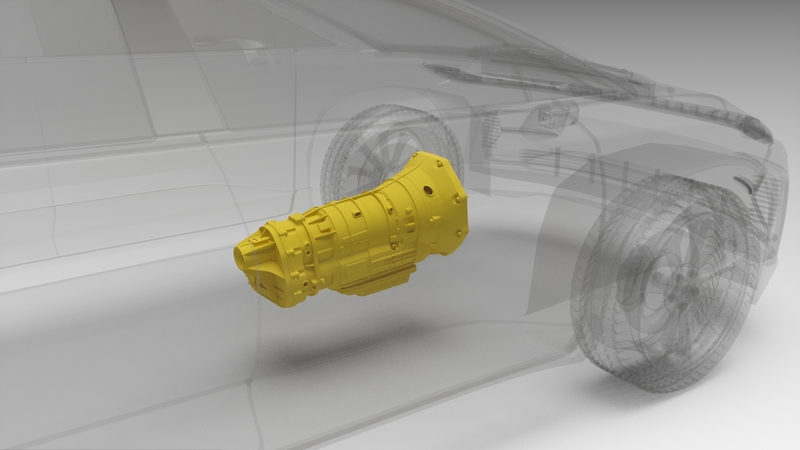

Back Ground

At Teijin Aramid we are constantly working at exceeding expectations both of engineers and drivers around the world. As the future of automotive design moves toward more extreme operational conditions, such as high temperatures and high torques, Twaron® Pulp, creates the strength and durability required of the friction paper, delivering a superior performance.

Overview

Our unique Twaron® para-aramid pulp allows the development of ultimate-performance friction paper for use in automatic transmission systems. Combining off-the-charts strength without compromising on porosity. These characteristics make it the perfect choice given the progressive decline in size and weight of tranmission systems. Depending on requirements, we offer various pulp types: short cut fibers and functionalized pulp types. These can be used as such or in combination to tune the required properties in the paper.

Features

Leveraging aramid pulp for fricition paper application in automotive means a more efficent energy transfer between engine and wheels all within a smaller lighter transmission design contributing to a superior transmission design and improved driving experience. Para-aramid and meta-aramid yarns have outstanding reinforcement properties and offer exceptional resistance to thermal, dynamic and chemical damage.

Key benfits of using Twaron® pulp are:

・High dimensional stability

・Thermal and chemical stability

・High strength and durability

・Good tribological properties

Back Ground

Around the world, manufacturers are taking advantage of the unique properties of Twaronb to make superior quality brake pads that offer top performance. Twaron® pulp delivers a positive driving experience with high levels of process efficiency and total reliability. More recently Teijin Aramid have produced partially or fully recycled Twaron® pulp for the brakes market.

Overview

The high-performance qualities of Twaron® have made it the material of choice for brake pad manufactures around the world. Compared to alternative fibers, Twaron® has superior thermal stablity, excellent arbrasion and chemical resistance, making long term reliable superior performance possible. With over 30 years experience in the industry, we are capable of producing pulp products to meet all desired performance criteria in the market.

Teijin Aramid is the only aramid fiber producer that offers pulps from new aramid, recycled aramids, and blends of recycled and new. Building on our long experience in manufacturing pulp, we offer a solution to lower the carbon footprint of the automotive industry without compromising on the performance and reliability expected for an important part.

Features

With its superior strength and durability, Twaron® is a high-quality additive that supports brake pad manuracturers to meet regulatory standards and surpass driver expectations.

The key benefits of using Twaron® in brakes are:

・Reduced noise, vibrations and harshness (NVH)

・Reduced wear

・Improved stabailty of edges and fewer cracks

・Higher strength

・Longer product lifetime

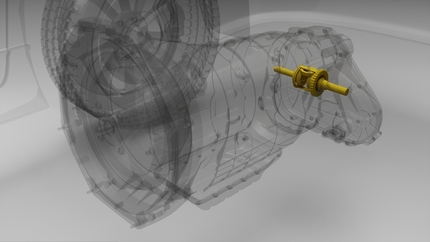

Back Ground

- There is an increasing need for quietness due to the characteristics required of automobiles.

- Twaron®, Technora®, and Teijinconex® can be used to reinforce various resins to create a quiet space inside the vehicle.

- Not only that, it's a light, strong, and attractive material that can reduce assembly costs.

Overview

- Twaron®, Technora®, and Teijinconex® are used in alternative resin gears for steel as materials to reinforce various resins.

- By using aramid fiber, it is possible to contribute to noise reduction, weight reduction, and improvement of fuel efficiency.

Features

Our short-cut aramid fibers create tough plastics, that combine maximum endurance with minimum maintenance. Using Twaron® or Technora® para-aramid fiber significantly enhances a compound's wear resistance, a key feature sought by engineers in gear design. Technora® is recommended for applications where more rigidity is desired. Additionally, with the use of Twaron® or Technora® based plastics, energy is dissipated efficiently and noise & vibration dampening is significantly improved.

The key benefits of using Twaron®, Technora® and Teijinconex® in engineered plastics are:

・High wear resistance, longer lifetime.

・Ability to engineer precisely the level of wear resistance required

・Self lubricating

・Lower weight

・Non-abrasive counter surface

・Reduction of noise & vibration dampening.